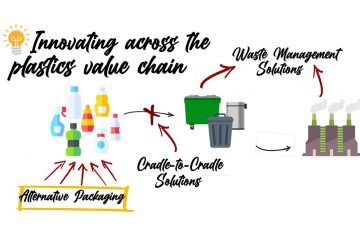

No more plastics: An Innovation

This article is the first of a three-part series on innovations across the plastics value chain. It’s difficult to imagine life without plastics. I know — plastics permeate virtually all aspects of our life. It’s Read more